Add to Cart

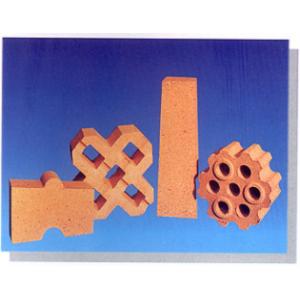

Low Porosity Clay Brick Refractory Fire Clay Bricks

Clay brick is a common kind of firebrick, also known as sintering brick.Refers to the alumina content of 30%~40% aluminum silicate made of clay products.Clay brick is composed of 50% soft clay and 50% hard clay clinker in accordance with certain particle size requirements.After forming and drying, it is fired at 1300~1400℃.The raw material of clay brick is clay, shale, coal gangue and other powder materials, and the mineral composition is mainly kaolinite (Al2O3 2SiO2 2H2O) and 6%-7% impurities (oxides of potassium, sodium, calcium, titanium and iron).

CH Refractoies will control each manufacturing process. Starting from the raw material into factory, Every production process of our product should through strict quality control, In addition to rigorous process control, our quality control team inspects the output of each process to ensure material quality and consistency. We do our best to supply the products with best quality to satisfy our customers.

| Items | Index | ||||||||

| / | CH-N-1 | CH-N2a | CH-N-2b | CH-N-3a | CH-N-3b | CH-N-4 | CH-N-5 | CH-N-6 | |

| Refractoriness /℃≥ | 1750 | 1730 | 1730 | 1710 | 1710 | 1690 | 1670 | 1580 | |

| 0.2Mpa Refractoriness under load(RUL)/℃≥ | 1400 | 1350 | 1320 | 1300 | |||||

| Reheating linear change/℃(1500℃,2h)

| 1400℃,2h | +0.1 -0.4 | +0.1 -0.5 | +0.2 -0.5 | |||||

| 1350℃,2h | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | |||||

| Apparent porosity/% ≤ | 22 | 24 | 26 | 24 | 26 | 24 | 26 | 28 | |

| CCS/Mpa ≥ | 30 | 25 | 20 | 15 | 15 | 20 | 15 | 15 | |

Applications of Fire Clay Brick:

Clay refractory brick plays an incomparable important role in the development of high temperature industrial kiln production, which is the indispensable basic alumina heat resistant material to ensure following production running and technological development.

Clay brick can be applied to

●Machinery and boiler

●Steel and nonferrous metals

●Glass, cement and ceramics

●Light industry and electric power

●War industry and other economic filed

Advantages of CH series Fire Clay Brick:

●Good thermal properties

●Resistant to acid slag and acid gases

●Resistant to rapid cooling and rapid heating

● Customerize mould according to different size requirements for free

●high bulk density,low apparent porosity,low creep,cheapest price in China,Free sample,Free construction guidance ,free 3D design